Critical Raw Materials: the importance of substitutes

Substitutability also plays an important role in determining the criticality of a raw material

Published by Matteo Nascone. .

Supercycle Critical raw materialsThe EU analysis on critical raw materials

Since 2011, the European Commission has periodically produced a list of what it considers to be "critical" raw materials (CRM) for

the European economy.

The 2023 study is particularly important because it defines the commodities that are the subject of the Critrical Raw Materials Act, document that identifies actions to reduce the vulnerability of the EU economy from risks deriving from possible shortages of raw materials. The act sets some benchmarks along the strategic supply chain of raw materials and the diversification of EU supplies by 2030.

It sets the following objectives:

- the EU extractive industry will have to produce at least 10% of the EU's annual consumption of each critical mineral;

- the EU processing industry will have to produce at least 40% of the annual community consumption of each critical raw material;

- at least 15% of the EU's annual consumption must come from recycling, for each critical raw material;

- no more than 65 % of the EU's annual consumption may come from a single third country.

The element of attention of the community is the possibility that European companies are unable to procure the raw materials necessary for their production. The criticality is therefore linked on the one hand to the supply risk and on the other to the importance (in terms of added value) of the user companies, whose activity could be interrupted due to the lack of raw materials.

For each critical raw material the Commission has quantified two summary parameters:

- the economic importance of the raw material (EI);

- the supply risk of the raw material (SR).

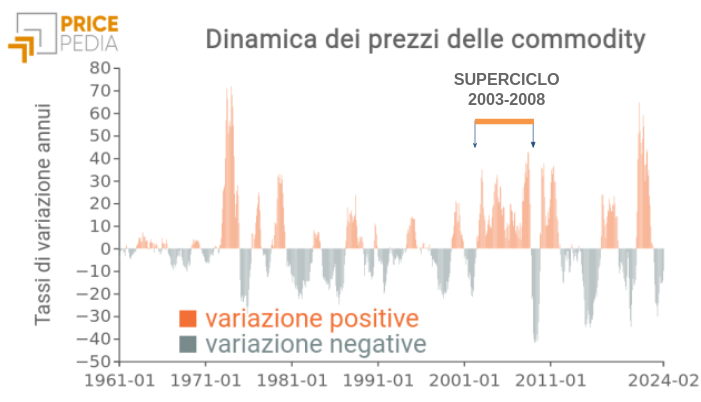

These parameters are calculated by combining a series of many other elementary parameters which together provide a particularly valuable set of information for the analysis of the markets for these raw materials. The detailed information used for the calculation of the two synthetic indices is in fact particularly useful for evaluating not only the "criticality" of a given commodity, but also the probability that this will record a phase of progressive increase in prices in the future, comparable to that which characterized the 2003-2008 supercycle.

Critical raw materials in the European context

Critical raw materials play a vital role for key sectors such as renewable energy and the digital industry. The European Union is highly dependent on imports, being exposed to availability risks accentuated by potential export restrictions by supplier countries.

For example, lithium and cobalt are fundamental for the production of lithium ion batteries used in electric cars and other technological devices as well as for the fuel cells from which clean electricity originates; borates are essential for the production of glass and ceramics; rare earths, thanks to their magnetic properties, find a vast range of applications, from aerospace and defense to renewable energy, up to consumer electronic devices such as smartphones and televisions.

The following table summarizes the 34 raw materials defined as critical in 2023 by the European Union on the basis of the two synthetic parameters already indicated: economic importance (EI) and supply risk (SR). The thresholds that allow defining a commodity that is important from an economic point of view and subject to high supply risk are established at community level.

List of raw materials considered critical by the EU Commission

| Famiglia | Materie prime critiche |

|---|---|

| Metals | Hafnium, Antimony, Beryllium, Bismuth, Cobalt, Gallium, Magnesium, Manganese, Platinum group metals, Nickel, Niobium, Copper, Strontium, Tantalum, Titanium metal, Tungsten, Vanadium |

| Minerals | Barite, Bauxite, Boron/Borate, Feldspar, Fluorite, Natural graphite, Phosphate rock |

| Rare materials | Scandium, Heavy rare earth elements, Light rare earth elements |

| Other raw materials | Arsenic, Coking coal, Helium, Phosphorus, Germanium, Lithium, Silicon metal |

Economic importance of critical raw materials

Economic importance (EI) is one of the two parameters identified by the Commission to evaluate whether a commodity can be considered critical or not. This indicator provides a perspective on the importance of a material for the EU economy in terms of the number of applications and the added value generated by the user sectors. The more numerous the applications of a raw material and the greater the added value created by the user sectors, the greater the economic importance of the raw material considered for the European economy.

Do you want to stay up-to-date on commodity market trends?

Sign up for PricePedia newsletter: it's free!

A crucial methodological aspect included in the calculation of this indicator is given by the replaceability of the raw material in its various applications. The more replaceable the raw material, the less important it becomes.

To calculate the substitutability of a raw material, the Commission examined the presence of substitute goods, their effectiveness in terms of alternative solutions to the raw material considered and their relative price. The more effective the substitutes are and the lower their price, the greater the substitutability of the raw material considered and, consequently, the lower its economic importance.

Conversely, the lack of valid substitute goods and their high price reduces the substitutability of a raw material, increasing its economic value.

Risk of supply of critical raw materials

Supply risk (SR) is the parameter defined by the Commission that reflects the risk of an interruption in the supply of a given commodity. The supply risk depends mainly on the degree of EU imports, the concentration of imports in a few countries and the governance of the supplier countries. It is measured both in the extraction phase of the raw material and in its initial processing phase.

Even in the case of supply risk, it is mitigated by the degree of substitutability of the raw material considered. The greater the substitutability, the lower the supply risk.

A further factor in reducing supply risk is given by the recycling rate at the end of the life of the goods that were produced using the raw material considered. It is calculated as the ratio between the production of all goods produced using recycled raw materials and the total production of the same goods, obtained using both recycled and virgin raw materials.

A summary vision

The following graph shows the 34 critical raw materials considered in 2023 by the European Commission, positioned on the basis of the values assumed by the two synthetic measures of economic importance and supply risk. Each commodity has values higher than both "critical" thresholds defined by the Commission, with the exception of copper and nickel which have a relatively low supply risk, but are still considered "critical" by the Commission due to the strategic role that these two metals have for the European industry.

The radius of the different balls shown in the graph is proportional to the degree of substitutability of the raw material considered: the higher this is, the wider the circle that represents it is.

From the analysis of the positioning on the map, these general lines emerge:

- Metals are positioned on average on the right side of the map, signaling their greater economic importance. Three of these metals (niobium, magnesium and cobalt) are also characterized by a high supply risk. Among the metals, these three present the greatest degree of criticality.

- The other raw materials are on average positioned on the left side of the map, indicating their relative lower economic importance compared to metals, in the specific meaning of the aspects considered here.

The graph clearly shows the importance of substitutability in determining the criticality of raw materials. The least substitutable raw materials tend to be positioned in the upper right quadrant of the graph, being relatively more important economically and with a risk highest supply. Conversely, the most replaceable raw materials are predominantly positioned in the lower left quadrant, being relatively less important economically and with a lower supply risk. The most striking case is that of copper, which is relatively economically unimportant and, above all, with a limited supply risk, thanks to its high degree of substitutability.

Conclusions

The analyses developed by the European Commission allow for in-depth knowledge of the 34 critical raw materials identified. The criticality of a commodity can be defined on the basis of supply risk and its economic importance. An important factor in determining the criticality of a raw material is its degree of substitutability.

The information obtained from the analysis of the criticality of a raw material can also be used to evaluate the price risk, meaning by this a phase in which the price of a commodity can record subsequent and significant increases, for a not short time.

However, the critical situation does not in itself lead to a new super cycle in commodity prices; for this to happen it is necessary, as we will see in a future article, that some determinants come into play, preventing a readjustment of supply in the face of significant increases in demand.