Update of zinc prices to May 2024

Analysis of financial benchmarks and zinc customs prices

Published by Luca Sazzini. .

Zinc Non Ferrous Metals Price Drivers

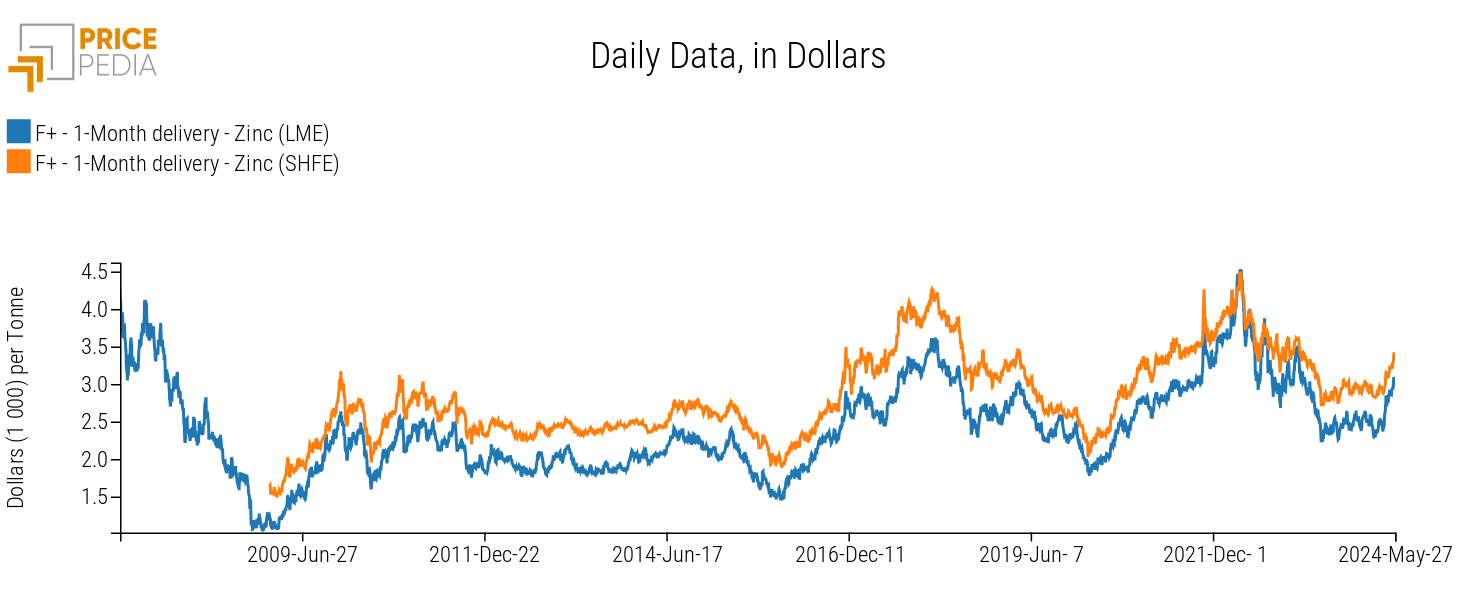

In the financial markets, there are two global benchmarks for zinc prices: the spot price quoted on the London Metal Exchange (LME) and the spot price quoted on the Shanghai Futures Exchange (SHFE). The first benchmark is the main reference point for Western zinc markets, while the second is the reference price for the Asian market.

The following chart compares the spot prices in $/ton of the two financial benchmarks for zinc prices.

Financial Benchmarks for Zinc Prices

Both benchmarks tend to follow the same dynamics but show differences in price levels. In particular, the Asian market price tends to be consistently higher than the European one. This price difference is attributable to the VAT included in the Chinese price, which for non-ferrous products is 13%.

For a more detailed analysis of financial zinc prices, the following table contains the annual averages from 2019 to 2024.

Table of Financial Zinc Prices, Expressed in $/ton

| 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|---|

| 1-Month Delivery-Zinc (LME) | 2546 | 2267 | 2996 | 3478 | 2646 | 2591 |

| 1-Month Delivery-Zinc (SHFE) | 2917 | 2647 | 3466 | 3726 | 3047 | 3017 |

From the analysis of the table, it is evident that the zinc price trend over the last 6 years is very similar to that of aluminum analyzed in the previous article:“Update of aluminium prices to May 2024”.

After a price decline in the 2019-2020 period, the recovery of global demand and rising energy costs led zinc prices to reach new highs in 2022. The weakness in global commodity demand in 2023 introduced a new phase of price reduction, which, in the case of zinc (unlike aluminum), continued slightly in the first 5 months of 2024.

To provide a more comprehensive view of zinc prices, the analysis of financial prices is extended to physical market prices in Europe.

Zinc Customs Prices in the EU

Within the European market, it can be useful to distinguish zinc from the commodities used in its production. The raw materials from which zinc can be extracted can be further divided into scrap derived from the recycling process and minerals used for the extraction of primary zinc.

Zinc Ore Prices

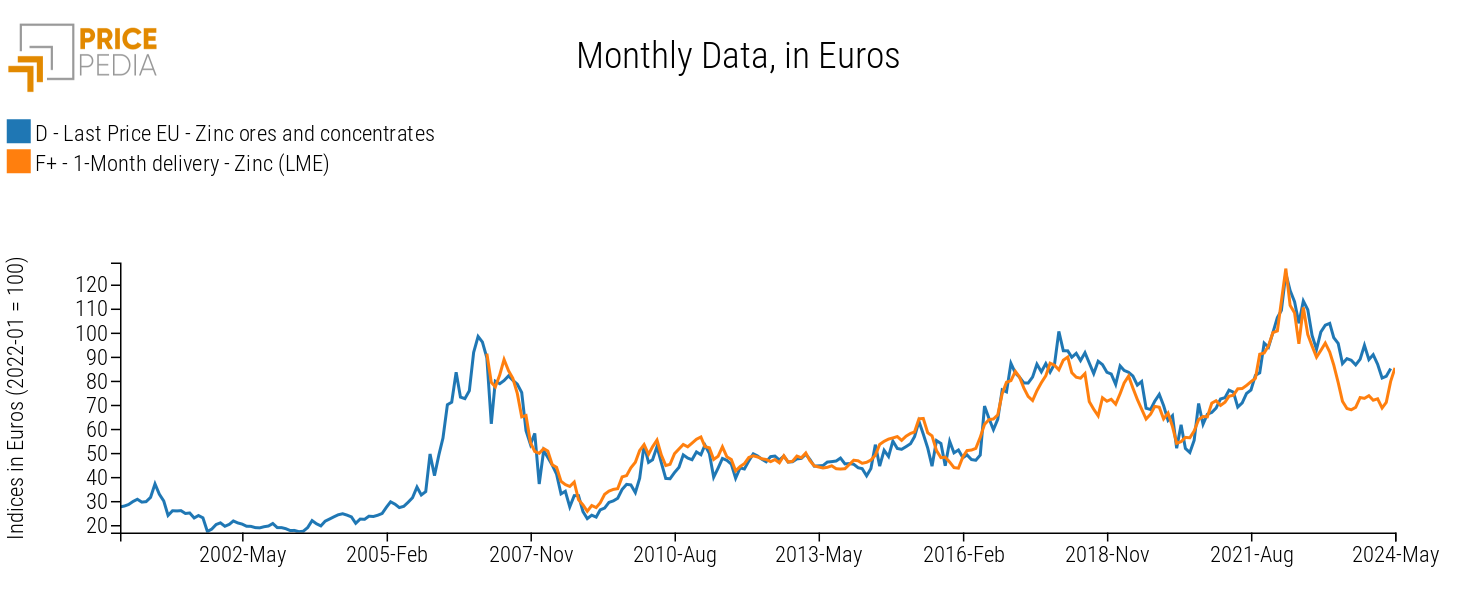

The following chart compares European customs prices of iron ores and LME zinc spot prices, expressed as an index with January 2022 as the base month.

Comparison of European Customs Prices of Zinc Ores and LME Zinc Spot Prices

From the analysis of the chart, it emerges that the historical series of European customs prices of zinc ores closely resembles the spot prices of zinc quoted on the London Metal Exchange (LME). The correlation between the two historical series is 0.96 out of a maximum of 1, indicating a strong direct relationship between the prices considered.

Do you want to stay up-to-date on commodity market trends?

Sign up for PricePedia newsletter: it's free!

Raw Materials for Secondary Zinc

Within the European market, the commodities used for the production of secondary zinc are zinc scraps and zinc hard zinc spelter from smelting. Scraps come from used products or industrial waste, while hard zinc spelter include slags, ashes, and powders from the smelting and refining process.

The following table contains the annual averages of the prices of the commodities used for the production of secondary zinc.

Table of European Customs Prices of Commodities Used for Secondary Zinc Production, Expressed in €/ton

| 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|---|

| D-Last Price EU-Zinc Scraps | 1752 | 1477 | 1706 | 2350 | 1919 | 1615 |

| D-Last Price EU-Zinc Hard zinc spelter | 1706 | 1503 | 1921 | 2504 | 1987 | 1803 |

The commodities for secondary zinc production also follow the same price trend as zinc, differing only in price levels. In 2019, the price of zinc scraps was generally higher than that of hard zinc spelter, but over the last 5 years, zinc hard zinc spelterhave become generally more expensive than zinc scraps.

Unwrought zinc and Zinc Dust

In the European market, zinc is traded both as unwrought zinc and zinc dust. Unwrought zinc is used for galvanizing steel or iron, which is a process of coating with a thin layer of zinc to prevent corrosion.

Zinc dust is mainly used for coating other metals through: cementation (Sherardizing)1, manufacturing metallic paints, or as a chemical reducer.2

Below is a table containing the annual averages of unwrought zinc and zinc dust prices traded in the EU.

Table of European Customs Prices of Unwrought zinc and Zinc Dust, Expressed in €/ton

| 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|---|

| D-Last Price EU-Unwrought zinc (weight ≥ 98.5% ≤ 99.95%) | 2425 | 2119 | 2610 | 3561 | 2874 | 2756 |

| D-Last Price EU-Unwrought zinc (weight ≥ 99.99%) | 2364 | 2059 | 2564 | 3419 | 2674 | 2609 |

| D-Last Price EU-Zinc Dust | 1968 | 2315 | 2418 | 2668 | 2039 | 2879 |

From the analysis of the table, it emerges that unwrought zinc shares the same price trend as other zinc prices, while zinc dust follows a different price dynamic. Zinc dust, in fact, begins a phase of price growth starting in 2019, and after the price decline in the 2022-2023 period, it records a strong increase in the first 5 months of 2024, reaching an average price of 2879 €/ton.

Conclusions

The two financial benchmarks for zinc prices have shown a common dynamic but slightly different price levels. The spot price quoted on the Shanghai Futures Exchange (SHFE) is slightly higher than that quoted on the London Metal Exchange (LME), due to the presence of VAT in the Chinese market, which is 13%.

Zinc prices in the European market have shown the same dynamics as financial prices, except for zinc dust.

Customs and financial prices of zinc recorded a decline in the 2019-2020 period, followed by a phase of price increase that ended in 2022, followed by a further decline that continued until the first 5 months of 2024.

[1] It is a coating process that involves heating steel parts in the presence of zinc dust in an oxygen-free environment, usually in a rotating drum. The heating causes the zinc to diffuse onto the surface of the steel, forming a protective zinc-iron alloy layer.

[2] Zinc give up electrons to other substances, facilitating chemical reactions that would otherwise be difficult to achieve.