The Complexity of Material Selection: Technical Criteria and Market Risk

A case study on the importance of assessing not only the technical performance of materials, but also their exposure to market risks

Published by Claudio Bruggi. .

technopolymers Procurement Risk ManagementIntroduction

Risk management in the supply of plastic polymers represents a crucial challenge for medium-sized companies involved in the design, development, and production of components for both consumer and industrial applications. This article analyzes a case study to illustrate how to address and mitigate the risks posed by polymer market volatility.

Company Context

Company Profile

The company in question is a medium-sized manufacturer specializing in injection-molded components made from engineered polymers. Its operations include the design, development, production, and marketing of products for consumer and industrial applications. Material selection is guided by several factors, such as required mechanical and rheological properties, material costs, and ease of molding. In addition, the company considers synergy with other components already in use, safety specifications, mechanical performance, and other considerations that may arise during product development.

Challenges in Material Management

The material selection process is often complicated by the need to balance high performance with costs and availability. Frequently, materials with specifications exceeding the minimum requirements for a given application are chosen to minimize potential risks. However, such choices can significantly impact inventory management and sourcing.

Challenges Encountered

Market Dynamics and Procurement

The company’s procurement team continuously faces challenges related to price volatility and the availability of polymers. Supply disruptions, sudden price increases, and partial information from distributors and producers further complicate the situation. The most immediate approach appears to be increasing inventory and securing prices through larger volume commitments, but this strategy is not always sustainable and often encounters resistance from the Finance department.

Internal Collaboration Challenges

The procurement team feels isolated and unsupported, perceiving that other departments, such as technical and production, do not fully understand the complexities and difficulties associated with managing raw material supplies. This isolation hinders collaboration and the sharing of essential information needed to effectively manage material-related risks.

Solution Approach

Risk Evaluation and Assessment

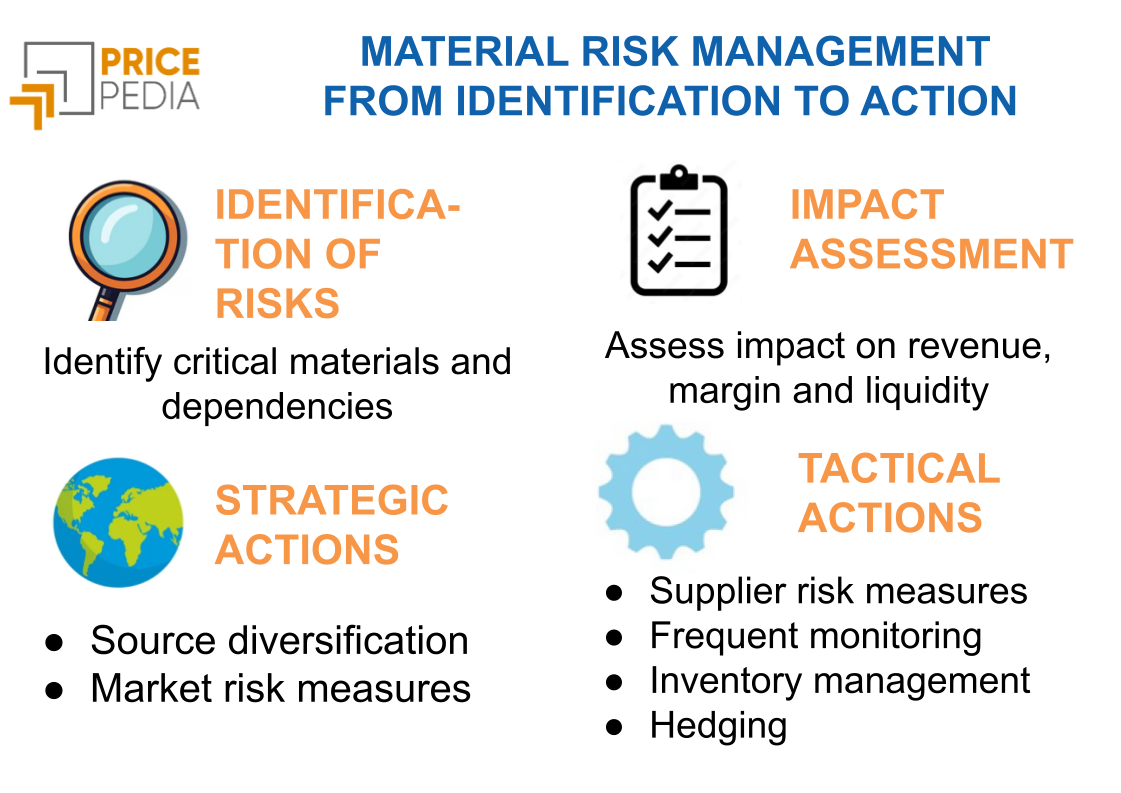

The first crucial step is to conduct a detailed assessment to identify and evaluate situations where the company is vulnerable to market conditions. This process includes:

- identification of critical products: listing all products and components whose supply depends on critical raw materials. These may include polymers with high source concentration or those produced in areas with geopolitical or infrastructural risks;

- impact assessment: estimating the impact on company revenue, margin, and liquidity resulting from complete or partial supply disruptions or indiscriminate price increases. The analysis should be calibrated across different severity levels (low, medium, high) to determine priorities.

Tactical and Strategic Actions

Possible tactical actions include:

- frequent monitoring: increasing the frequency of monitoring polymer markets to detect price and availability changes promptly;

- inventory management: raising stock levels and improving visibility in scheduling to reduce the impact of market fluctuations;

- hedging: where possible, identifying price drivers and determinants linked to market commodities to enable the use of financial hedging tools.

Beyond tactical actions, a strategic action could be source diversification, i.e., replacing critical materials with alternatives available in more stable markets, reducing dependence on suppliers and high-risk regions.

Innovative Tools

In a perspective of collaboration and involvement of the purchasing department in technical choices impacting business risks, would it not be beneficial to have a risk index associated with each material’s market?

If such an index were available, then the company’s technical or R&D departments could, along with purely technical and functional criteria, also evaluate the risk index associated with the polymer market before deciding which materials to adopt.

Conclusions

Material selection in a project is guided by both technical and economic criteria, but rarely includes consideration of the market risk associated with different materials. This limitation is partly due to the slow adoption of innovative tools within companies and partly due to the lack of reliable metrics for assessing market risks.

Implementing reliable measures of market risk could not only enhance material selection decisions but also foster greater collaboration and mutual understanding among the procurement, technical, and production departments. A more integrated risk management approach would help minimize misunderstandings and support stronger strategies to handle market fluctuations.