Update of steel tube prices to December 2024

What characteristics most affect steel tube prices?

Published by Luca Sazzini. .

Ferrous Metals Steel tubes Price DriversSteel tubes are highly specialized industrial products, designed to meet a wide range of application needs. Thanks to their versatility, they are fundamental components in numerous sectors, including construction, energy, and manufacturing.

There are various types of industrial tubes involved in international trade, each with distinctive characteristics that can significantly affect the price.

Among the many properties that differentiate steel tubes, the ones that have the greatest impact on the final product cost are:

- the production process based on extrusion or welding of rolled sheets: welded tubes are generally more economical than non-welded ones, as they require less energy consumption compared to extruded tubes;

- the precision level: precision tubes are designed to meet the needs of applications requiring very high levels of quality and accuracy, which makes them significantly more expensive than standard ones;

- the type of steel used: the choice of steel significantly affects the final product price. In particular, it is useful to distinguish stainless steel from other types such as carbon steel.

This article presents an analysis of steel tube prices, divided into the following categories: welded steel tubes, non-welded steel tubes, precision steel tubes, and stainless steel tubes.

Price Analysis of Welded Steel Tubes

Welded steel tubes are made starting from a steel sheet, which is passed through a series of rollers to give it the desired geometric shape. Once shaped, the edges of the strip are overlapped and welded together, creating a continuous joint along the tube. This process, thanks to its high efficiency, reduces labor costs and production times compared to extrusion-based methods.

Below is a table containing the average annual prices of welded steel tubes, expressed in euros per ton.

Table of Average Annual Prices of Welded Steel Tubes, Expressed in Euro/Ton

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| D-Last Price EU-Welded steel tubes for gas, threaded | 724 | 1137 | 1384 | 1136 | 1038 |

| D-Last Price EU-Welded steel tubes for gas, galvanized | 789 | 1051 | 1364 | 1167 | 1108 |

| D-Last Price EU-Welded steel tubes, galvanized (diameter ≤ 168.3 mm) | 865 | 1226 | 1550 | 1268 | 1108 |

| D-Last Price EU-Welded steel tubes, others (diameter > 168.33 mm ≤ 406.4 mm) | 688 | 1023 | 1284 | 1106 | 1000 |

| D-Last Price EU-Welded steel tubes (diameter > 406.4 mm) | 713 | 943 | 1212 | 1183 | 1131 |

| D-Last Price EU-Welded steel tubes non-round (thickness ≤ 2 mm) | 682 | 1187 | 1277 | 997 | 917 |

| D-Last Price EU-Welded steel tubes non-round (thickness > 2 mm) | 636 | 1130 | 1193 | 942 | 881 |

The prices of welded steel tubes tend to follow a common trend, characterized by an initial growth phase from 2020 to 2022, followed by a subsequent decline up to the present day.

In terms of levels, steel tube prices are relatively similar to each other, but with slight differences based on their specific properties.

Non-round tubes stand out for their lower price, resulting from the greater simplicity of their production process. Next come the tubes intended for gas transportation, whose prices are lower due to less demanding production standards and their use in less specialized applications, which do not require resistance to particularly extreme conditions, such as heavy loads or high pressures.

The welded steel tubes with the highest prices are galvanized ones, due to the additional galvanization treatment, the greater precision required in processing, and their use in sectors that demand high resistance and durability.

The diameter size alone, however, does not appear to be a decisive factor in determining tube prices.

Analysis of Unwelded Steel Tube Prices

Unwelded steel tubes are produced through an extrusion and piercing process starting from steel billets, which are initially perforated to obtain a raw tube, subsequently subjected to hot or cold rolling. This production process is longer and more complex than welding, but it ensures superior product quality, making it particularly resistant to high pressures and mechanical stresses.

The table below reports the prices of the main unwelded tubes most traded in the European market, expressed in euros per ton.

Table of Average Annual Prices for Unwelded Steel Tubes, Expressed in Euros/Ton

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| D-Last Price EU-Unwelded Steel Tubes for Pipelines | 885 | 1026 | 1605 | 1540 | 1320 |

| D-Last Price EU-Unwelded Steel Tubes for Threaded Gas | 967 | 1164 | 1904 | 1913 | 1765 |

| D-Last Price EU-Unwelded Steel Tubes for Drilling | 1203 | 1278 | 2254 | 2654 | 2164 |

| D-Last Price EU-Unwelded Steel Tubes, Others (diameter ≤ 168.3 mm) | N.A. | N.A. | 1571 | 1489 | 1233 |

| D-Last Price EU-Unwelded Steel Tubes, Others (diameter > 168.33 mm ≤ 406.4 mm) | N.A. | N.A. | 1623 | 1593 | 1307 |

From the table analysis, it emerges that the prices of unwelded steel tubes, in addition to being generally higher, follow a different trend compared to welded ones. Except for tubes with diameters between 168 and 406 mm, all other types of unwelded tubes recorded a continuous increase in annual prices from 2020 to 2023, followed by a decline starting in 2024.

Among unwelded steel tubes, the most expensive ones are those intended for drilling, as they are designed to withstand extremely harsh conditions, such as high pressures, elevated temperatures, and corrosive environments. On the other hand, pipeline tubes stand out for their lower price, resulting from a less complex and more standardized production process, as they do not require the same levels of resistance and durability demanded for other applications.

Do you want to stay up-to-date on commodity market trends?

Sign up for PricePedia newsletter: it's free!

Analysis of Precision Steel Tube Prices

Precision steel tubes are characterized by extremely tight dimensional tolerances and a finely polished surface. These features require a highly complex production process, which results in a high final product cost.

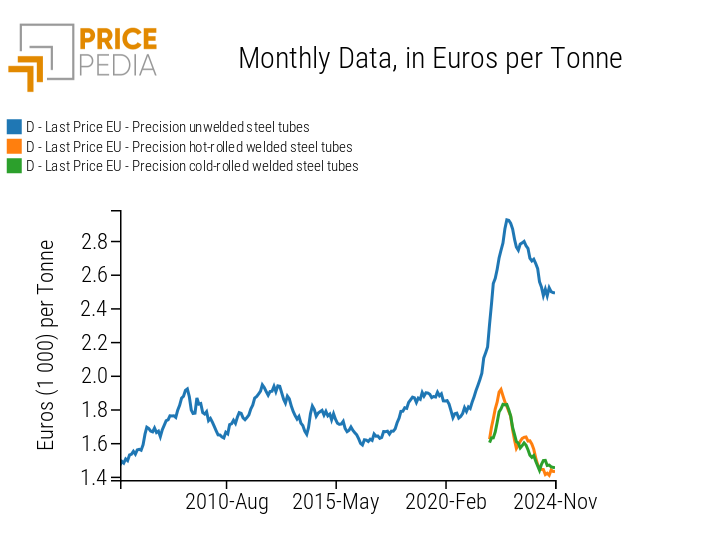

Below are the historical series of European customs prices for precision steel tubes, expressed in euros per ton.

Historical Series of Precision Steel Tube Prices, Expressed in Euros per Ton

The analysis of the graph reveals that welding is a crucial factor in determining the final price of the product. In fact, seamless precision steel tubes tend to cost 1000 euros/ton more than welded ones. Conversely, the price difference between hot-rolled and cold-rolled welded steel tubes is practically negligible.

Analysis of Stainless Steel Tube Prices

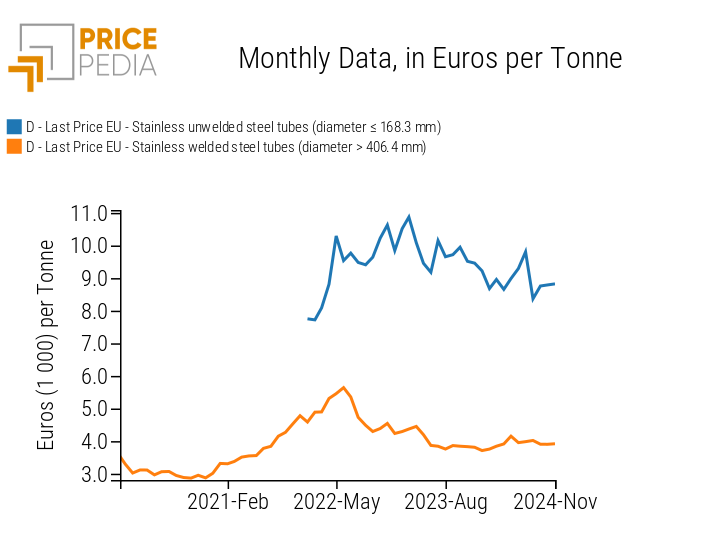

Stainless steel tubes are distinguished by greater corrosion resistance, due to their high chromium content, which is equal to or exceeds 10.5%. In addition to protection against corrosion, stainless steel offers high mechanical strength, resistance to high temperatures, and wear, making it ideal for a wide range of metallurgical applications.

The following graph presents a comparison between welded and seamless stainless steel tubes.

Historical Series of Stainless Steel Tube Prices, Expressed in Euros per Ton

The graph analysis highlights the high price levels of stainless steel tubes. During the peak period, welded stainless steel tubes exceeded 5500 euros/ton, with prices being four times higher than those of standard welded tubes.

As for seamless stainless steel tubes, they even surpassed 10,000 euros/ton in 2022, reaching prices approximately five times higher than those of standard seamless tubes.

Conclusions

It is interesting to observe how the specific characteristics of steel tubes not only influence price levels but can also modify their dynamics. In particular, it has emerged that welded steel tubes show a distinct price trend compared to seamless tubes. This topic will be explored in subsequent articles, where the main factors determining the price dynamics of various types of tubes will be examined.